Home > Company Profile

Company Profile

Taipei Headquarters |

Dongguan Factory |

Shenzhen Office |

|

Taipei Office |

Meeting Room |

Conference Room |

|

Staff Lounge |

Warehouse |

Warehouse |

|

|

|

|

|

|

|

|

|

| WALTHER-WERKE | GALLTEC | BECK | |

|

|

|

|

|

|

|

|

| WALTHER-WERKE CEO VISIT EVERLEAD TAIWAN ─ July,2019 | |||

Company Profile

Everlead Global Inc. is a supplier of electrical equipment, telecommunication devices, automatic control systems, and machinery parts and components. Since establishing of the company, we insist the business philosophy of professionalism, integrity and serve. We are committed to providing customers with high-quality products, professional technology, and competitive prices, aim to help customers achieve higher performance for their products and eventually EVERLEAD will become customers’ trustworthy partner.

Apart from represented well-known industrial products from Europe, USA, UK and Japan, we own a specialized electromagnets (solenoids) factory with 10 production lines of more than two decades experience in innovating, designing and manufacturing electromagnets (solenoids). We are proud of having good quality production and test facilities, the strictest quality control process, the staffs have good technic qualifications, the R&D engineers have the ability and enthusiasm to design and develop products based on customer’s demands and applications. EVERLEAD provides one stop service including designing, manufacturing, testing and quality control, domestic sales and export sales of electromagnets (solenoids).

Our customers spread all over the world, covering a variety of industries: electronics, communications, electrical, steel, semiconductor, textile, knitting, industrial machinery, engineering, automatic control, motorcycles and vehicles, locking system, vendor machine, food machine, OA machine, building, stage lightning, refrigeration and air conditioning, electrical appliances, etc. Our main products are electromagnets (solenoids), terminal blocks, CEE plugs and sockets, NEMA plugs and receptacles, GFCI, junction boxes, proximity switches, photoelectric switches, sensors, industrial multi-pole connectors, surge protector, junction boxes, pressure switches, differential pressure switches, pressure transmitters, humidity switches, temperature and humidity transmitters, index drives, inclinometers, accelerometers, load cells, breakers, searchlights for shipbuilding, CCTV, RFID, and so on.

In the future, we will continue to strengthen sales channels, expand product categories, and improve our expertise. We will continue to grow and thrive with our customers and manufacturers.

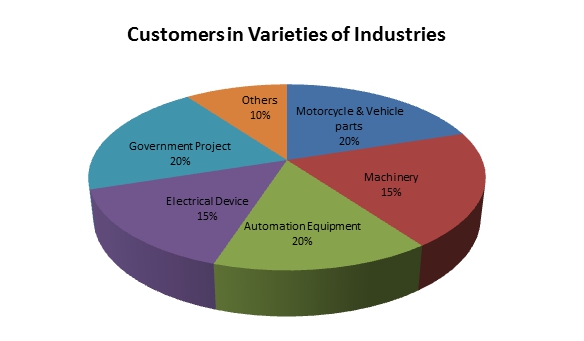

Customers in Varieties of Industries

Manufacturing Capacity

1. 10 production lines for solenoid assembly

2. Monthly capability 1.5 million

|

|

|

|

|

|

|

|

|

|

|

|

Product Picture

|

|

|

|

| Solenoid & Actuator |

Solenoid |

Electromagnet (electric scooter) |

Customised Solenoid - B0E0H1 |

|

|

|

|

| Customised Solenoid- ELK0356SL |

Customised Solenoid | Customised Solenoid – SF32A150L |

Customised Solenoid – ELB2C8L |

|

|

|

|

| Customised Solenoid – 180221LA1 |

Customised Solenoid - 170928LA4 |

Customised Solenoid – ECM4975H |

Customised Solenoid - EL171103 |

|

|

|

|

| Customised Solenoid – 180221LA1 |

Customised Solenoid – F170928LA4 |

Customised Solenoid – CM4975H |

Customised Solenoid - EL171103 |

|

|

|

|

| Customised Solenoid - EL09A5 |

Customised Solenoid – M170610P |

Customised Solenoid – EL0940TZ |

Customised Solenoid – ELAC05 |

|

|

|

|

| Inclinometer |

OTSUKA |

Limited Angle Torque Motors |

THIN RELAY |

|

|

|

|

| Quick connector |

Gland & Junction Box |

Surge Protector |

NEMA |

|

|

|

|

| Cam Switch |

GFCI |

Fuseless Switch |

Sensor Proximity Switch |

|

|

|

|

| Heavy Duty Connector |

MIL-DTL Connector Ressure |

Transmitter |

Plug & Socket |

|

|

|

|

| Dipole |

Terminal Block |

Flow Sensor |

Pressure Switch & Pressure Transmitter |

Hardware Processing Capacity

High accuracy hardware processing equipment

♦ CNC machines

♦ Citizen high accuracy hardware processing equipment

♦ Several sets semi-automatic lathe

|

|

|

|

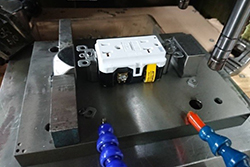

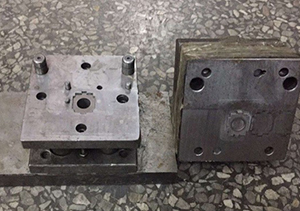

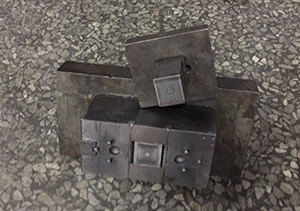

Tooling Capacity

Focus on mold related technology research and development, pay attention to the product precision, has rapid Mold design, manufacturing and Service ability, let each process are completed in the factory. Using CAE/CAD/CAM computer aided engineering to improve productivity, reduce the number of, shorten products development cycle, reduce the mold manufacturing cost.

|

|

|

|

Injection Molding

| Double Injection Has advanced injection molding equipment, can provide customers with two different material (PC, PC/ABS, TPU, TPE,TPEE, etc.) and injection of double color parts, equipment specifications. |

|

| Precision Injection With advanced international brand injection molding machine, equipment specification of 50T, 80T, 100T, 130T, 150T, 160T,180T, 230T, 350T. |

|

|

|

| No. | Main Inspection and Testing Equipment |

|

| 1 | Roughness tester | |

| 2 | Temp HD Controller | |

| 3 | Life Tester | |

| 4 | Projector | |

| 5 | Salt Spray Tester | |

| 6 | Resistance Tester | |

| 7 | Resistance Tester | |

| 8 | Pulsing Tester | |

| 9 | Tension Tester | |

| 10 | Rubber Hardness Tester | |

| 11 | Transport Simulator | |

| 12 | Drop off Tester | |

| 13 | 28db Noise Tester |